Busy Start to the Year for GBS Engineering & ATR Products…..

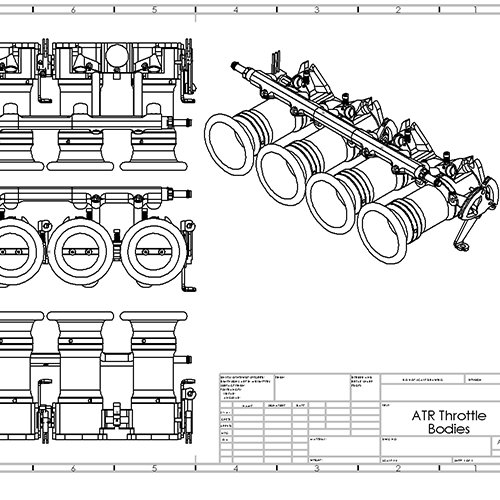

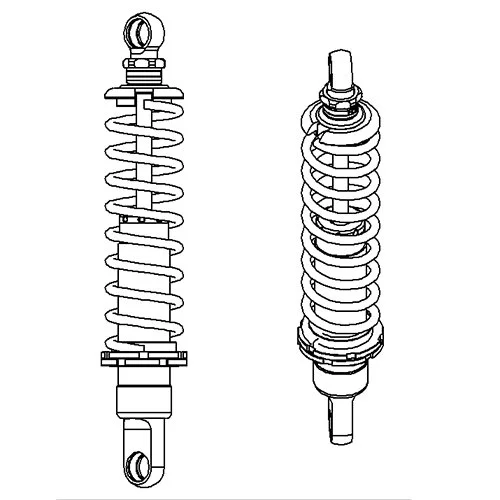

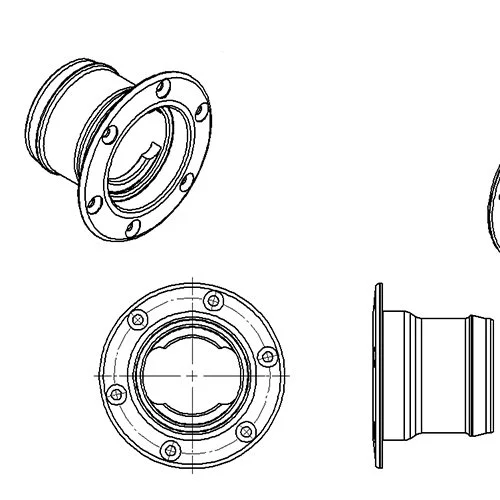

/It’s been a busy and productive start to the year within the GBS Engineering department, with continued growth and strong demand across our ATR Products range. Developed in-house, ATR Products provide a selection of high-quality upgrades and optional extras designed to enhance the performance, functionality, and finish of the Zeros.

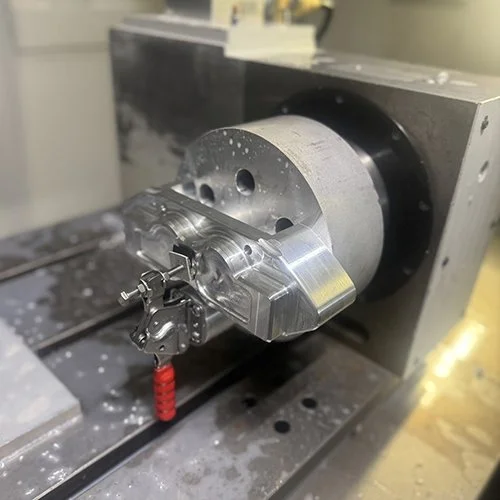

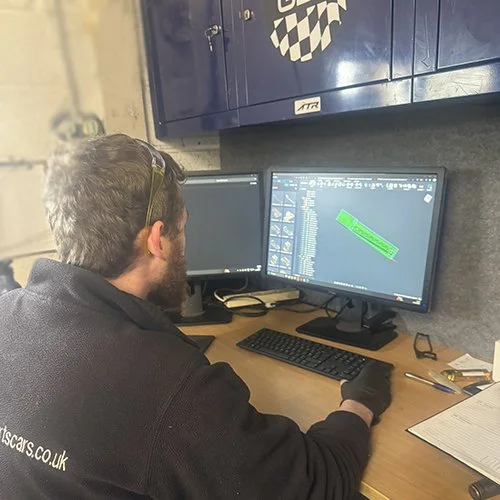

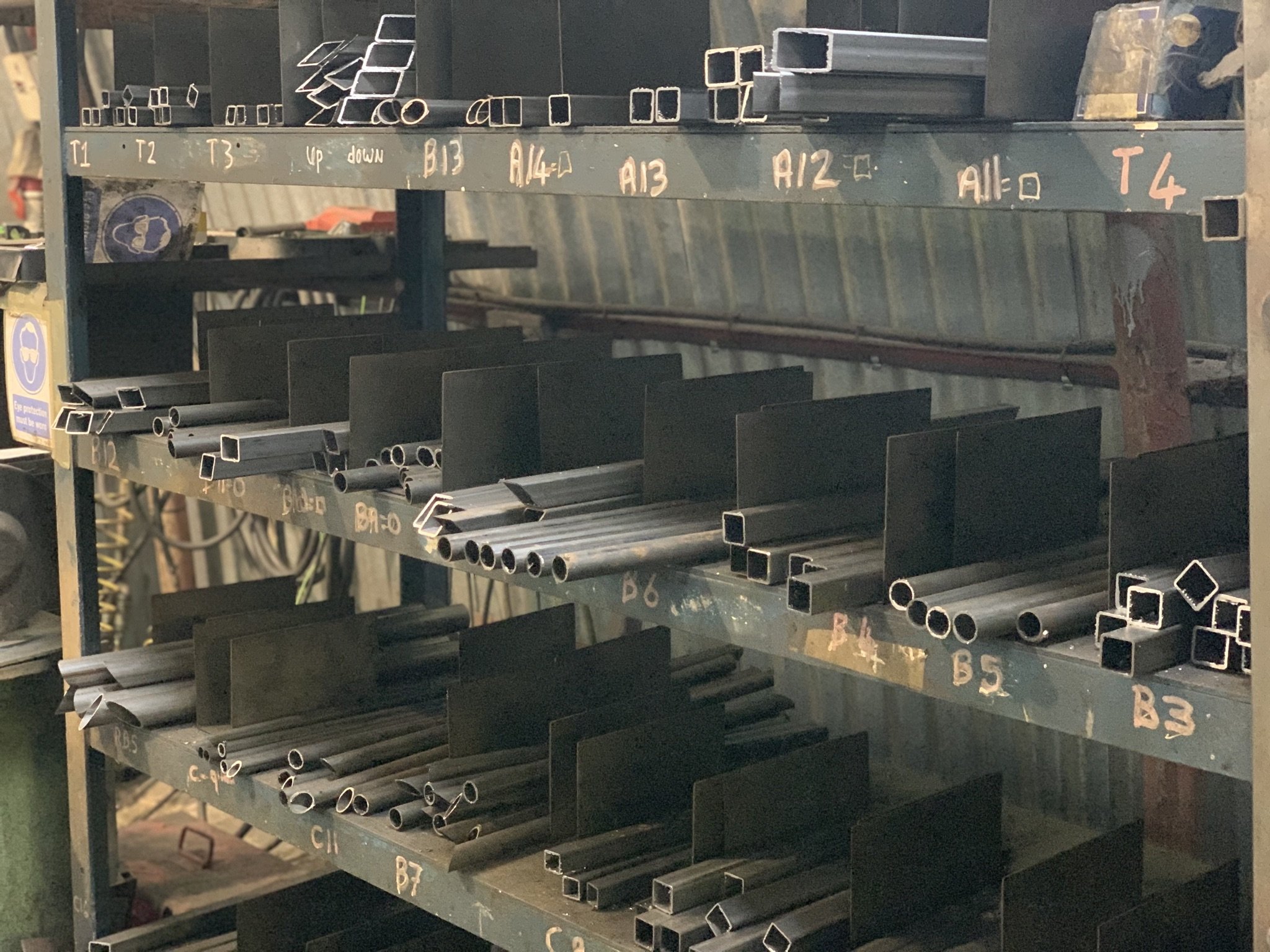

We are proud that around 80% of the Zero is manufactured in-house, reflecting our commitment to British engineering, quality control, and continuous development. This capability allows our team to innovate quickly while maintaining the precision and consistency customers expect from GBS.

The year has begun at great pace, with our CNC machines running consistently to produce a variety of exciting components across the ATR range and some other bespoke projects we have been working on.

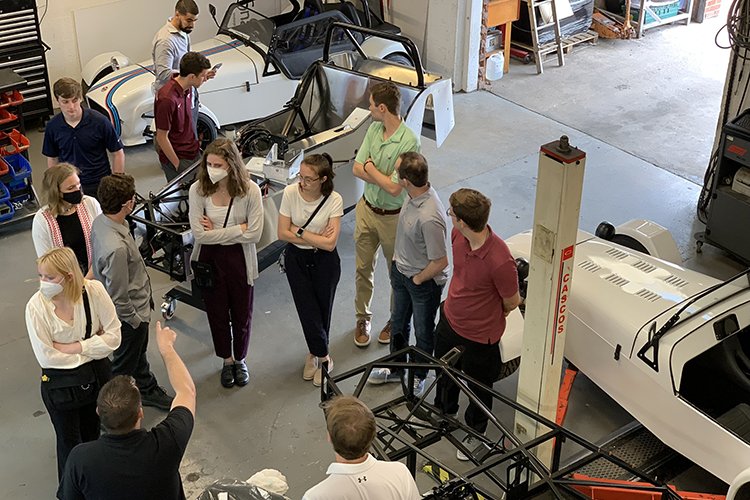

Below is a selection of recently manufactured products highlighting the diversity of the ATR offering. Visitors to the Race Retro Show this weekend (20th-22nd February) will also have the opportunity to see a range of ATR Products on display, alongside a latest Zero Race car build -featuring an extensive selection of ATR components.

If you’re attending the show, be sure to visit our GBS stand in Hall 2 to explore the products in person and speak with the team about how ATR upgrades can support your own Zero project. All the ATR Products are available online from our parts website Kit Spares, explore more here - www.kitspares.co.uk