Innovating together - Hydrogen and Value-Added-Carbon production through Waste Heat Recovery: Hy-Value Recovery.

We are proud to announce that an exciting project is now underway along with a consortium of businesses. This project will embed new manufacturing technology in the UK and contribute to decarbonisation of the Foundation Industries.

'Hydrogen and Value-Added-Carbon production through Waste-Heat-Recovery' (Hy-Value Recovery) will up-scale a manufacturing process for a sustainable, affordable, value-added-carbon product for the Foundation-Industry Chemicals sector through utilising high-grade waste-heat from steel/glass furnaces.

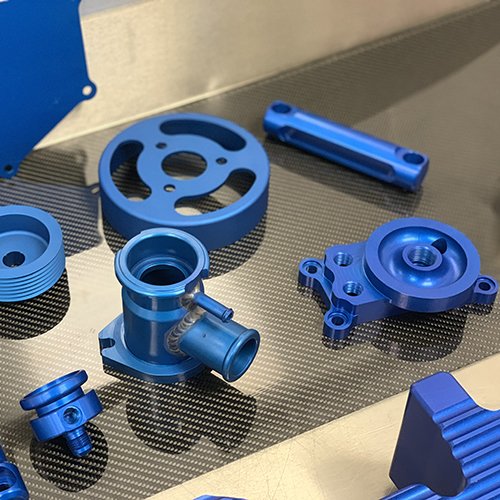

Q-Flo's Value-Added-Carbon product range, Torstran, is produced by high temperature processing of methane/hydrocarbon feedstocks including renewables/wastes (e.g. from land-fill, biogas, hot-steel reaction gases) to give a carbon nanotube product in a safe bundled structure.

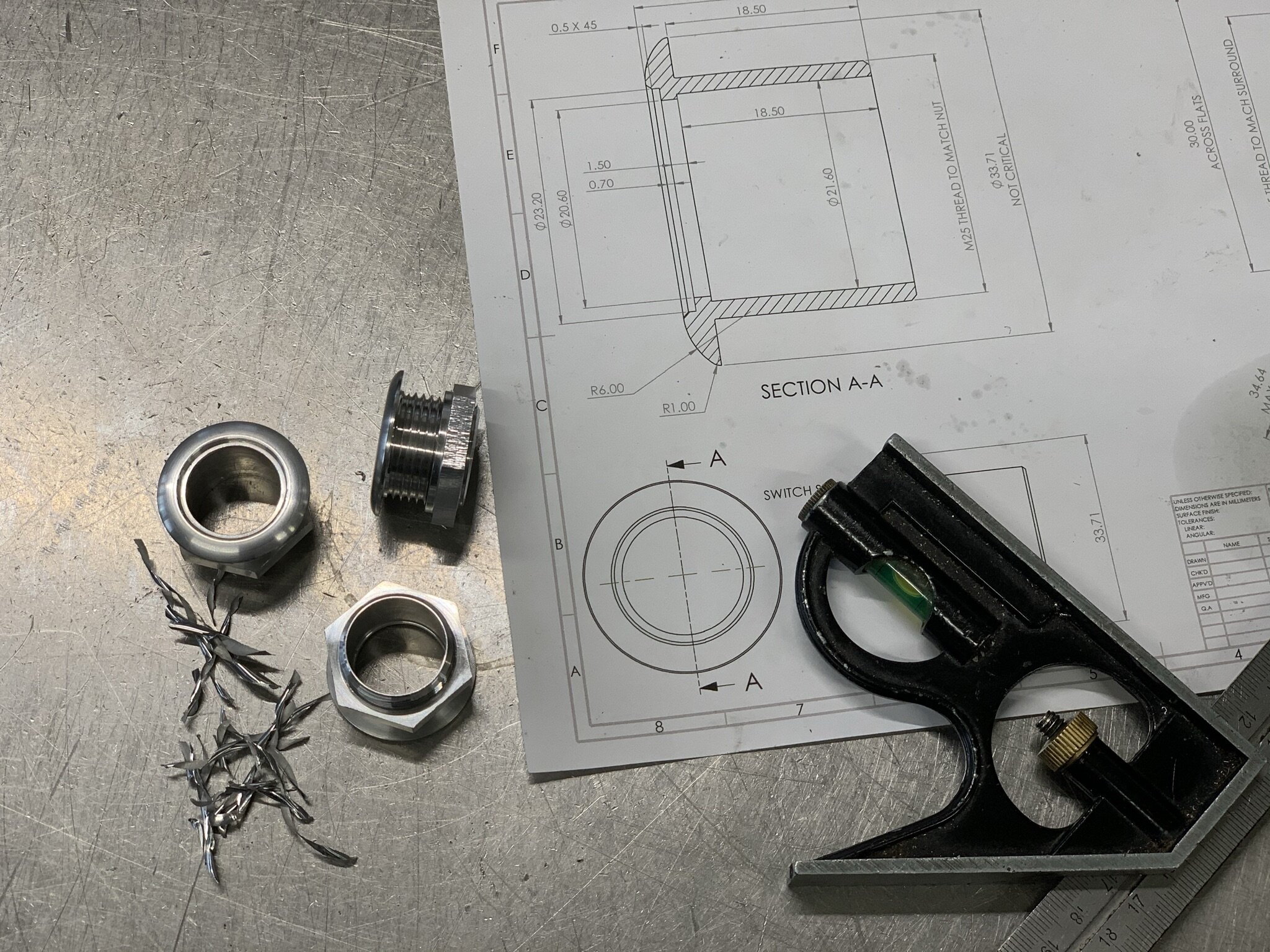

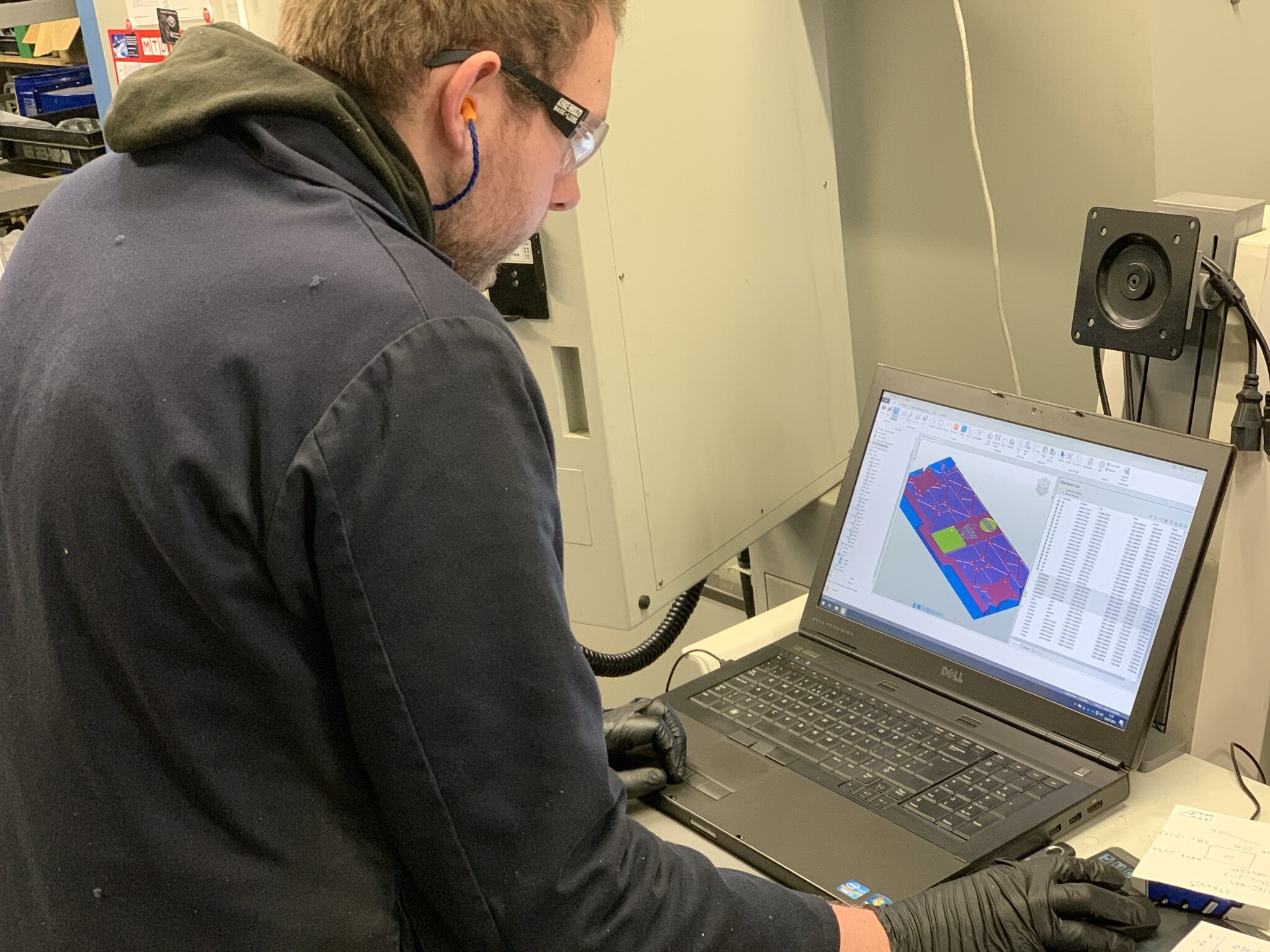

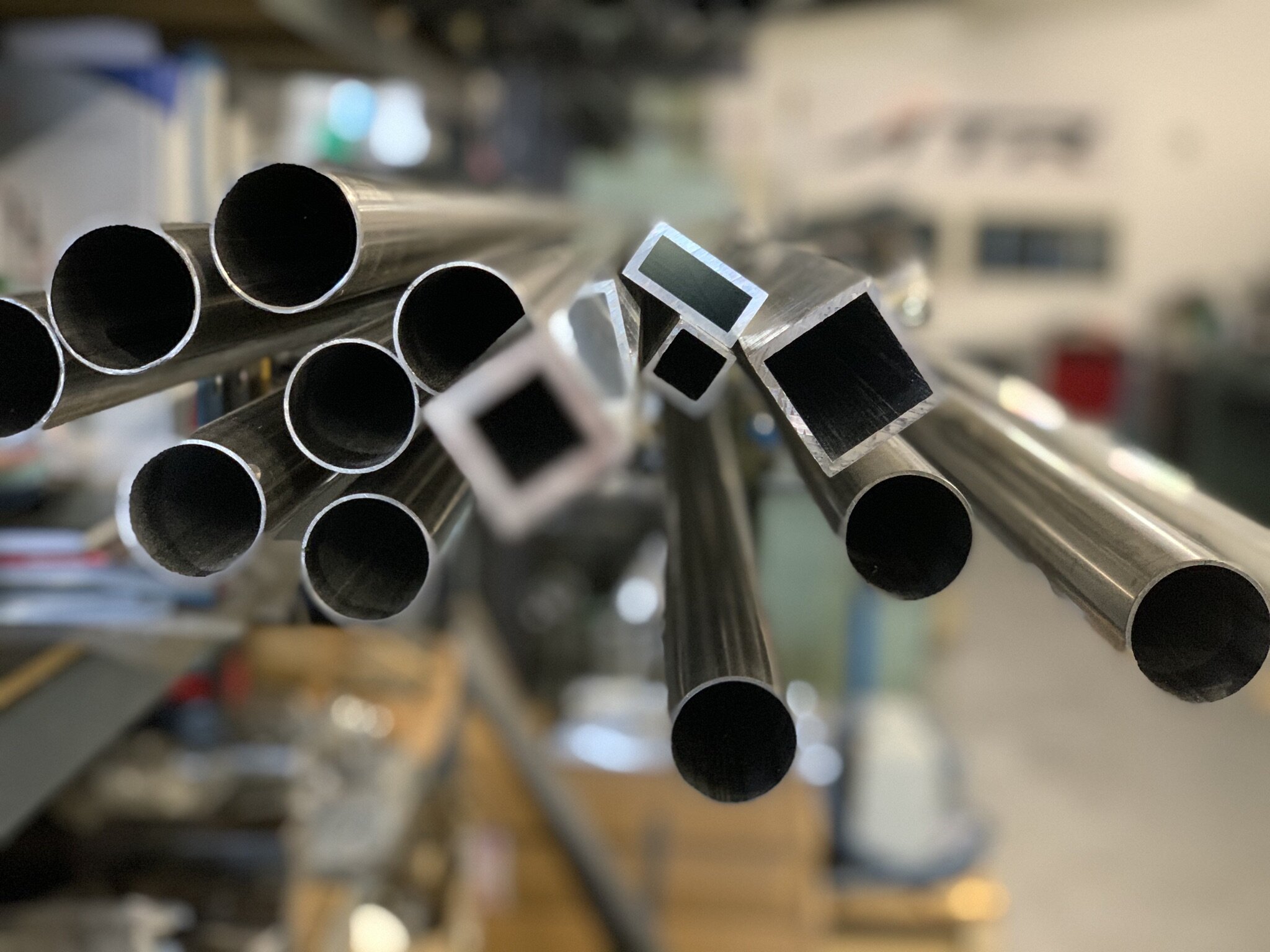

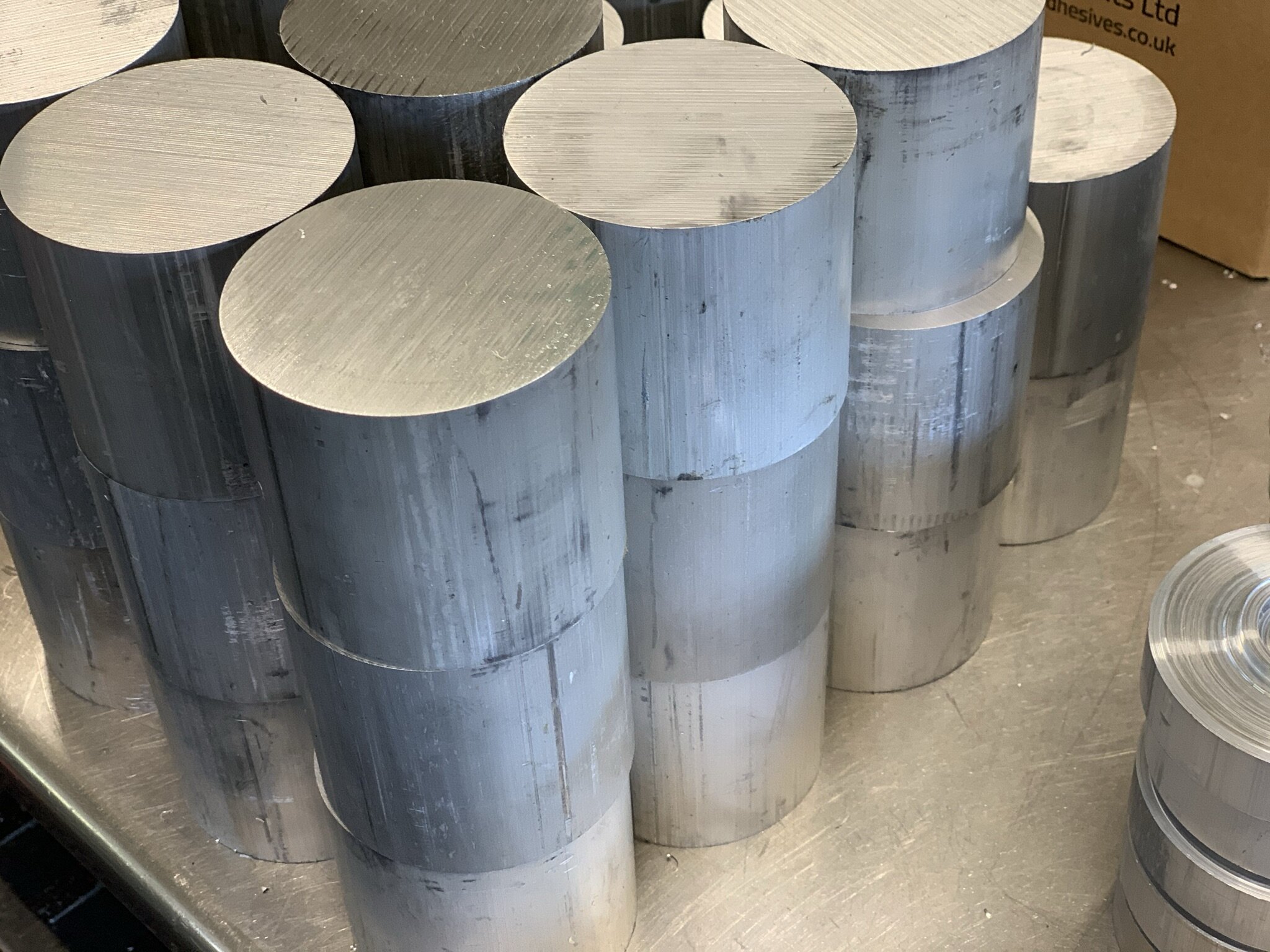

Hy-Value Recovery' will develop / build / operate an industrially-relevant-scale Torstran-Production-Demonstrator, at Glass Futures pilot plant in St Helens, Merseyside, demonstrating continuous 24-7 operation at an industrially-relevant scale, producing large volumes of Torstran and pure hydrogen for evaluation within industrial, aerospace and automotive applications.

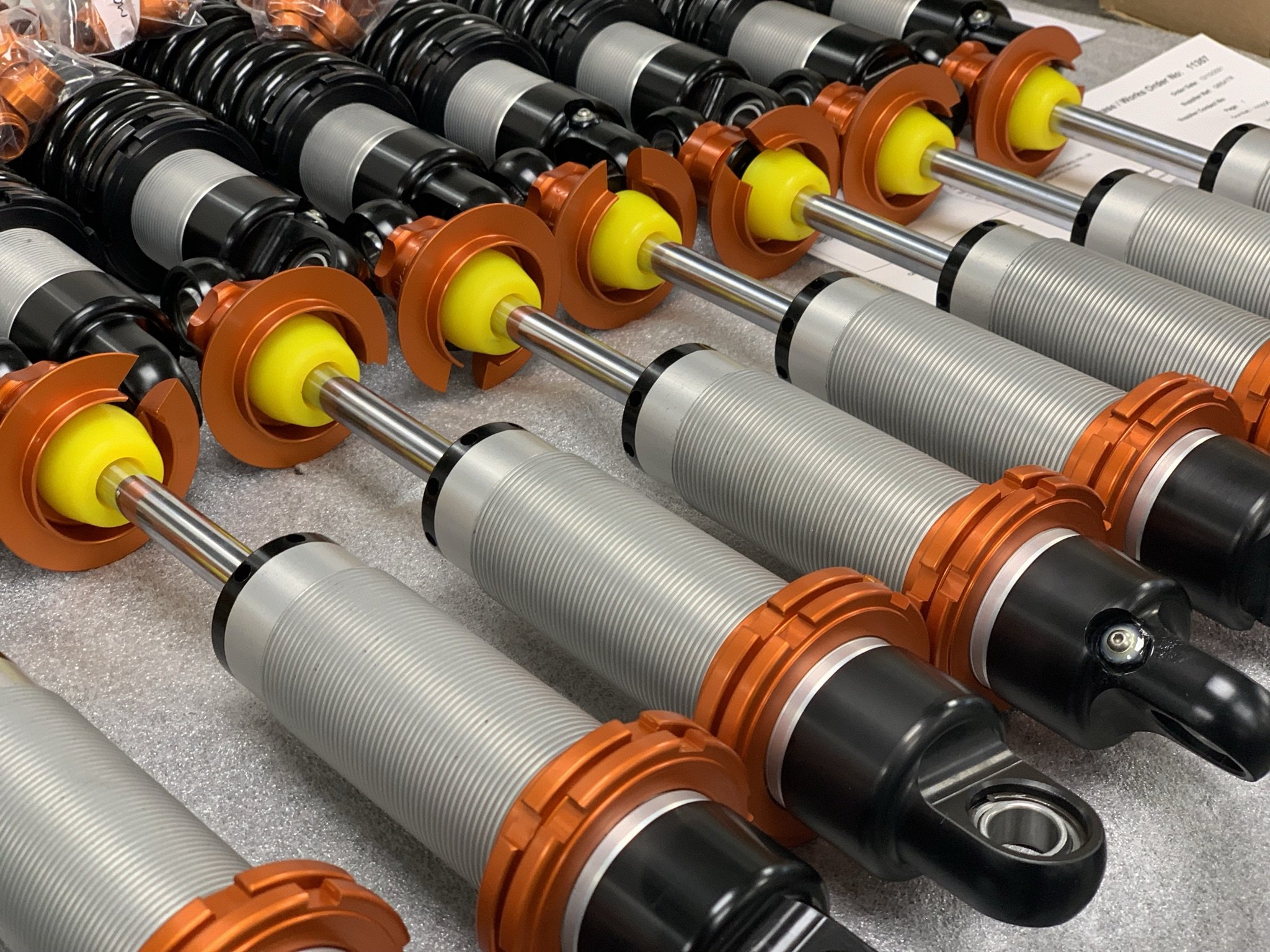

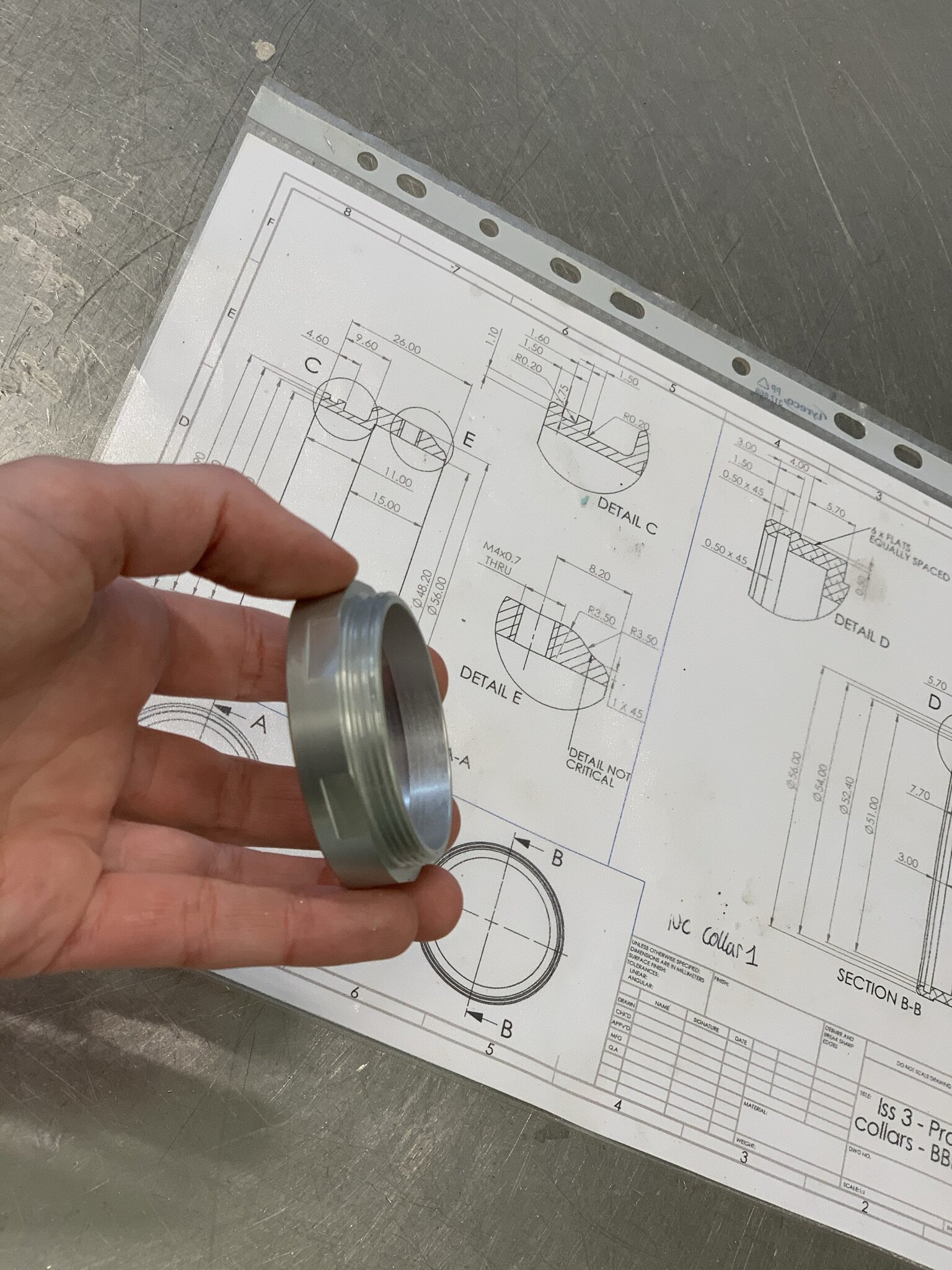

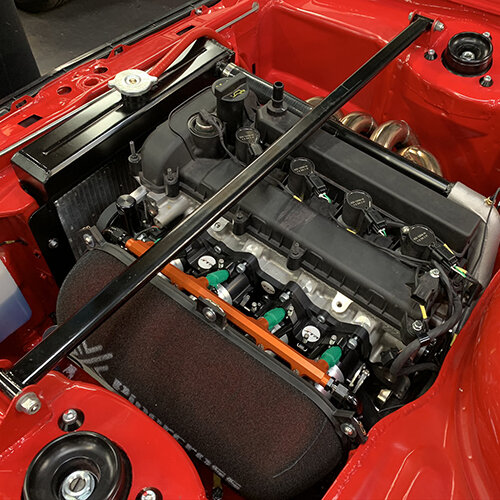

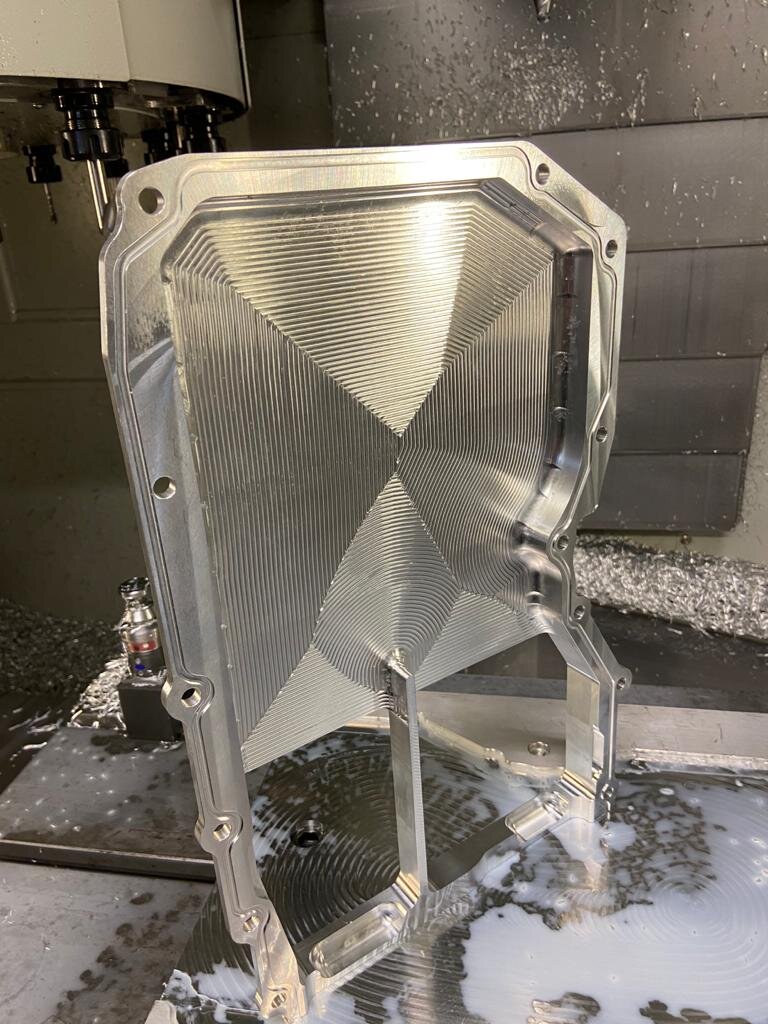

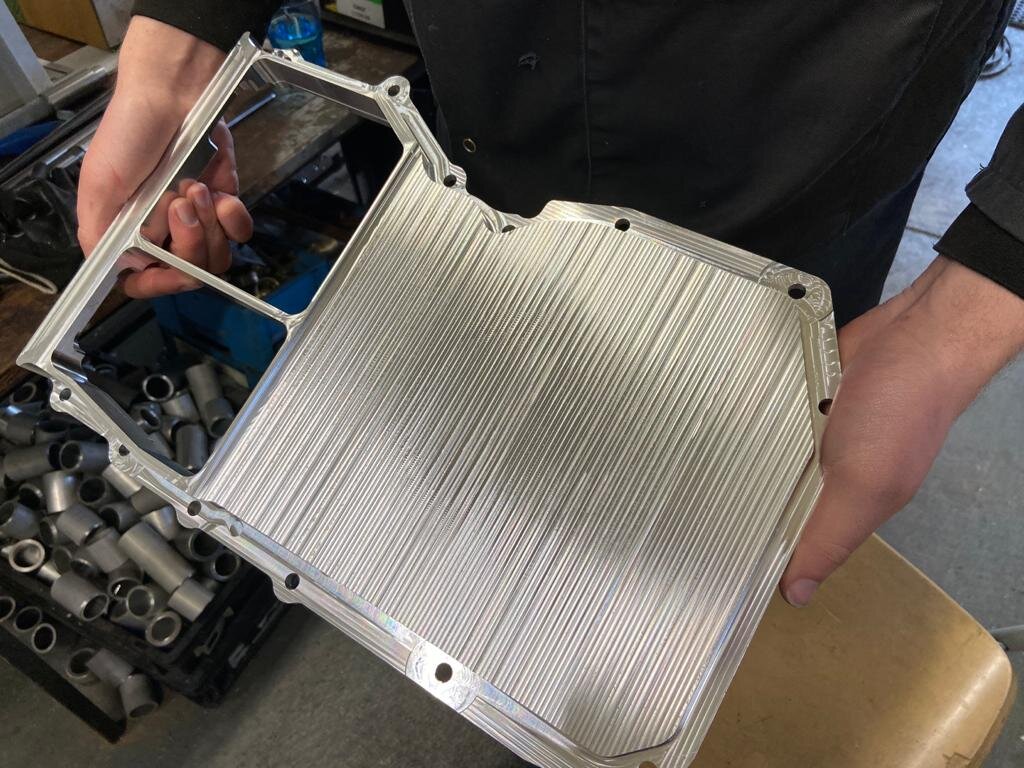

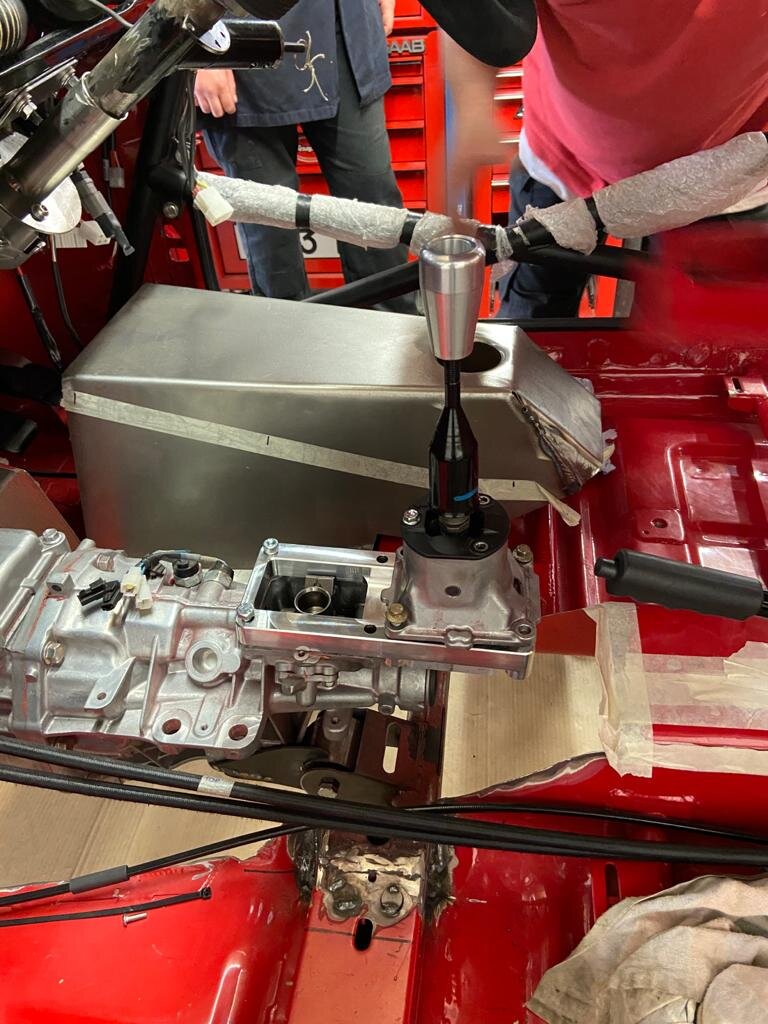

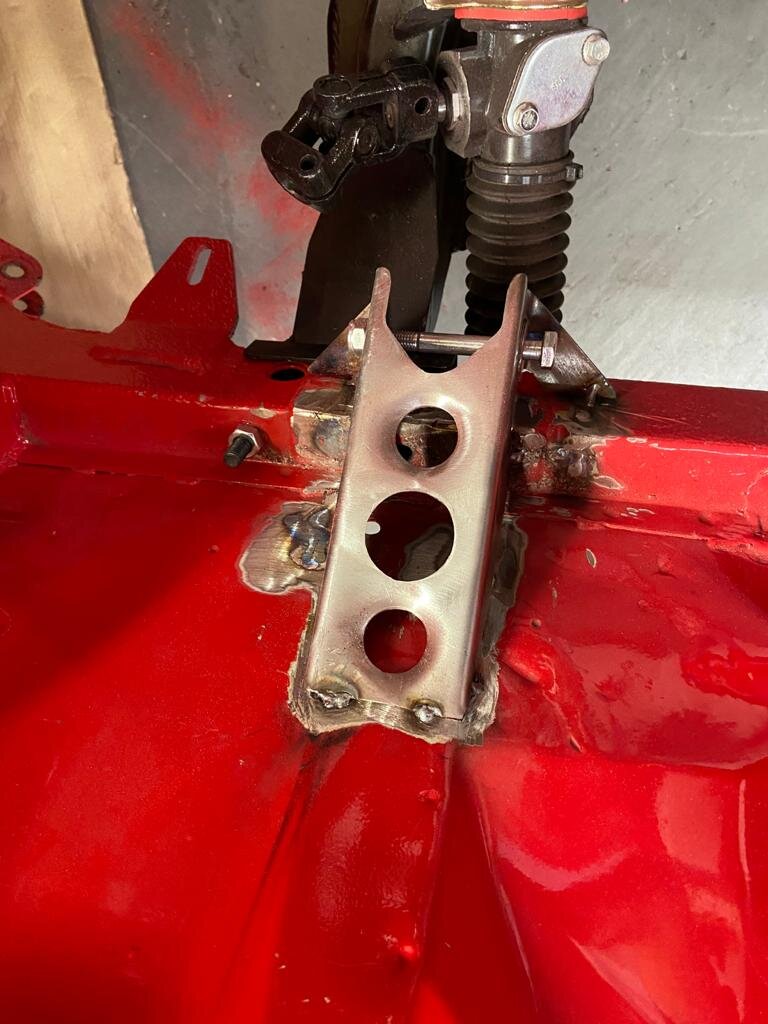

Tata Steel UK will evaluate integration with their operations, use of the hydrogen by-products as a process-gas in annealing ovens, and explore use of Torstran to add functionality to their products. University of Cambridge and Glass Futures will evaluate Torstran coatings on glass/steel. Almath Crucibles will evaluate Torstran-enhanced ceramics. Torstran has demonstrated excellent potential for electromagnetic interference (EMI) shielding and as a composite in reduced-weight electric vehicles. Great British Sports Cars and United Aerospace will lead further optimisation/ validation/ electric vehicle trials.

Martin Pick, Q-Flo - “The Hy-Value Recovery project is a tremendous boost to the development of this technology. The project and its partners bring expertise, knowledge and resources which will be invaluable in helping us achieve our mission to scale the carbon nanotube production process and become key supply chain partners in exciting emergent markets. Innovation from University of Cambridge, along with support from Innovate UK, has been crucial to this and we are very pleased the manufacturing is now beginning in the UK”

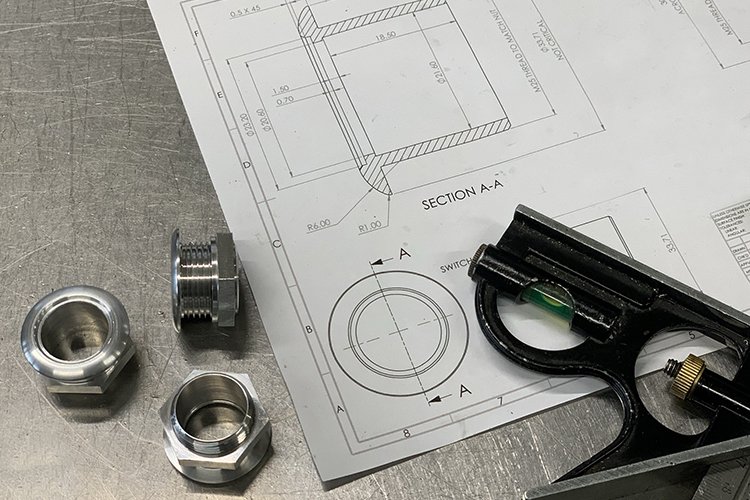

Richard Hall, Great British Sportcars - “Great British Sports Cars (GBS) are pleased to have been awarded this project along with Q-Flo and other partners and are very much looking forward to working with the Project members to develop these new applications and opportunities that we can demonstrate the processing and manufacturability of the material in novel real world applications.”

Rob Ireson, Innovation and Partnerships Manager at Glass Futures - "Glass Futures (GF) are delighted to be working with Q-flo on this project to develop new techniques for improving the efficiency of its Torstran manufacturing processes through the utilisation of the waste heat energy from industrial processes. We will host the technology at our pilot facility and demonstrate its continuous operation on our new 30T/day furnace to show how this can be applied to commercial glass furnaces.

“We believe that the ultra-long carbon nanotube materials produced with this process have potential to add value to a range of applications and products manufactured within the Foundation Industries (FI), such as new conductive coatings and improved industrial abatement technologies. GF are very much looking forward to working with the Project team to develop and evaluate these new application opportunities and establish itself as a global centre for FI development”

The funding was provided through Innovate UK’s Transforming Foundation Industries challenge which is helping energy-intensive businesses to share expertise and come up with radical new innovations to help reduce their carbon footprint. It is part of UKRI’s Challenge fund which is bringing together the UK’s world-leading research base with our best businesses to transform how we live, work and move around.

Bruce Adderley, Innovate UK Challenge Director for the Transforming Foundation Industries Challenge, added: “Underpinned by circular economy thinking, the Foundation Industries and their supply chain partners are bringing forward a range of new innovations as they move towards a sustainable competitive future. But these need to be demonstrated at scale if they are to be rapidly deployed in the UK and taken to international markets. That is why we are delighted to be able to support projects like Hy-Value Recovery that are up-scaling manufacturing processes to develop and evaluate new application opportunities that will significantly reduce the carbon footprint of foundation industries, create high-value jobs, and make it internationally competitive.”

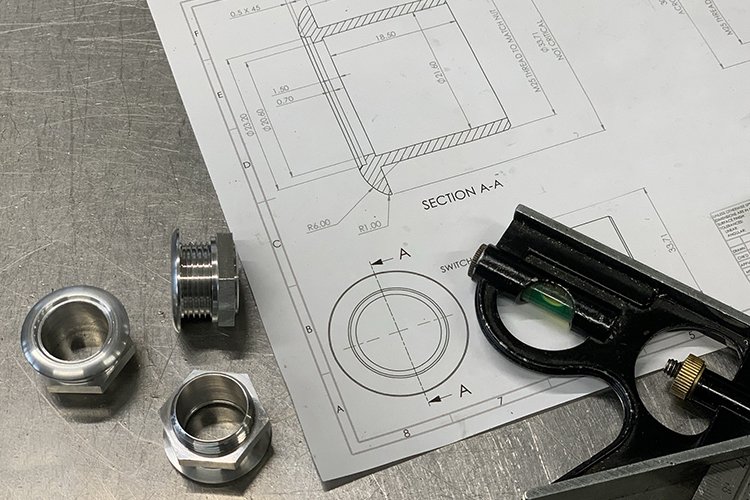

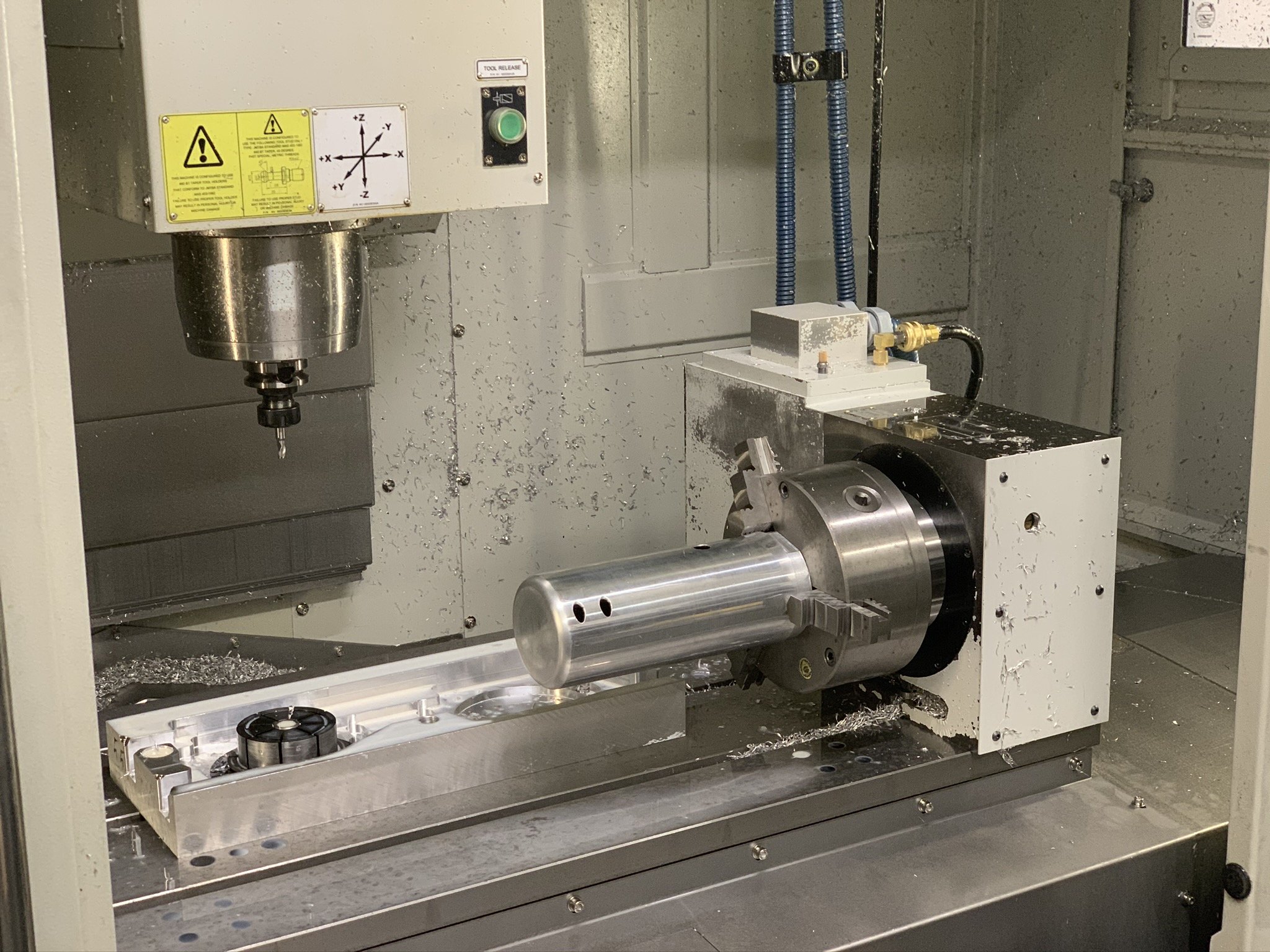

The outcome for GBS in this project will be to produce a demonstrator vehicle showcasing the technology in the real world which will demonstrate the processing and manufacturability of the material in finish components. This project is now underway and further updates will be shared later this year as the project develops.